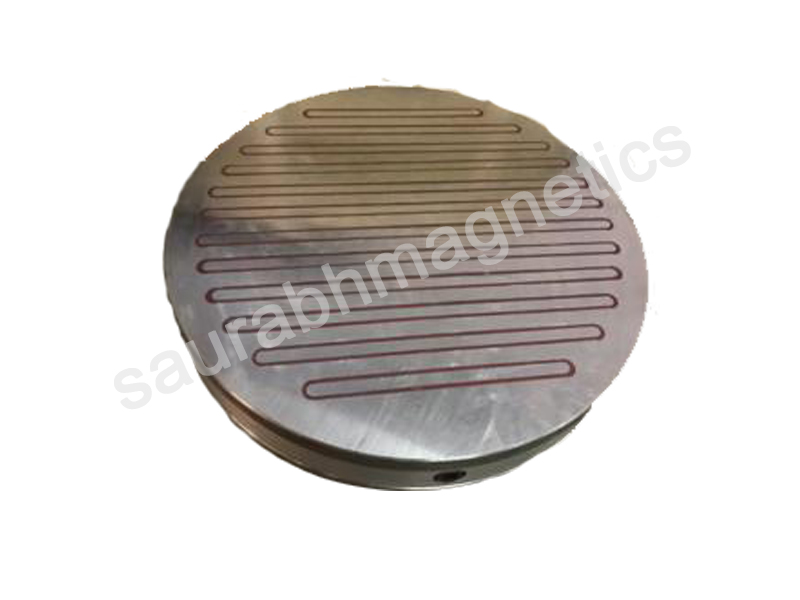

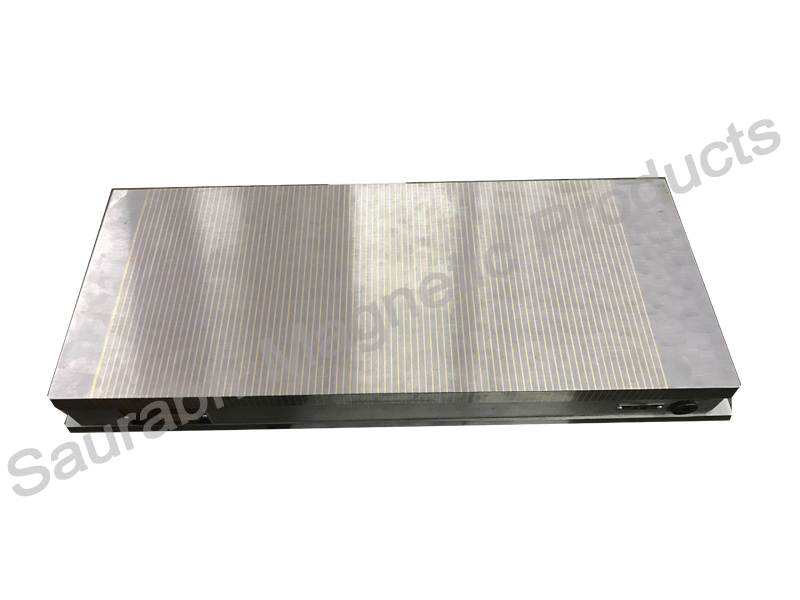

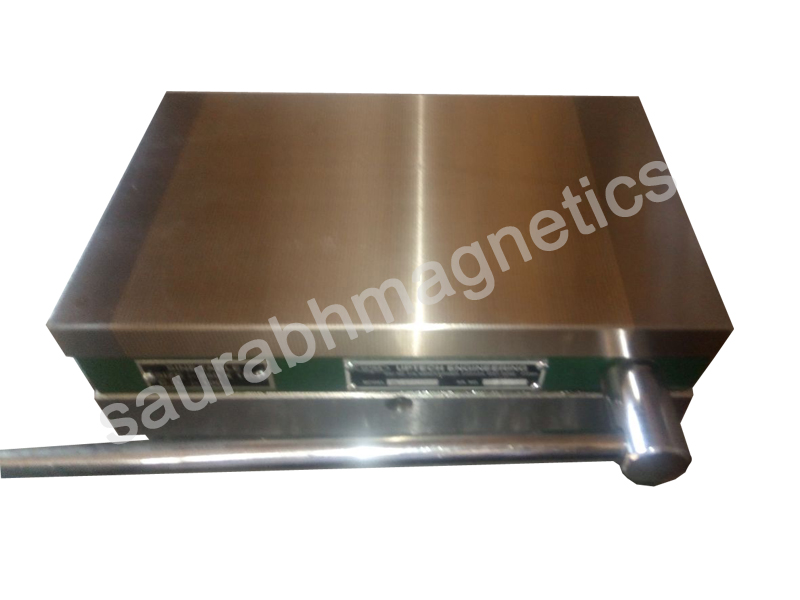

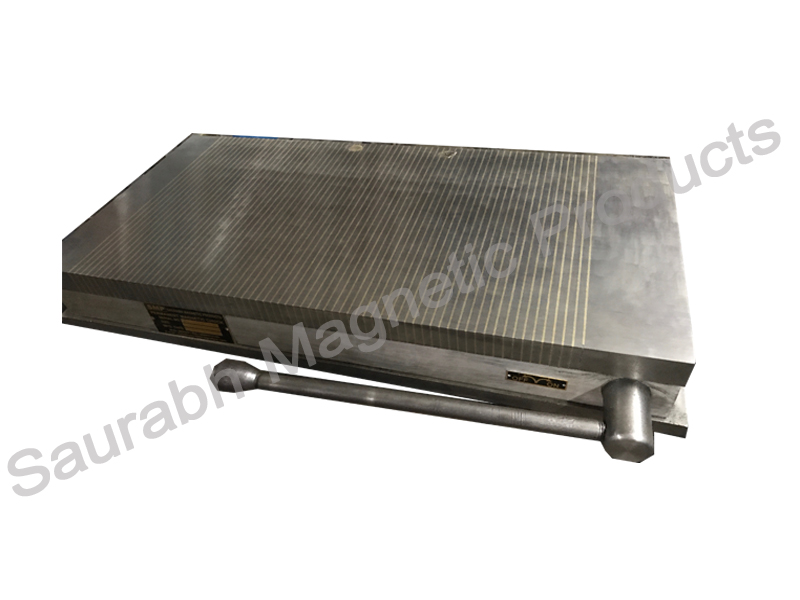

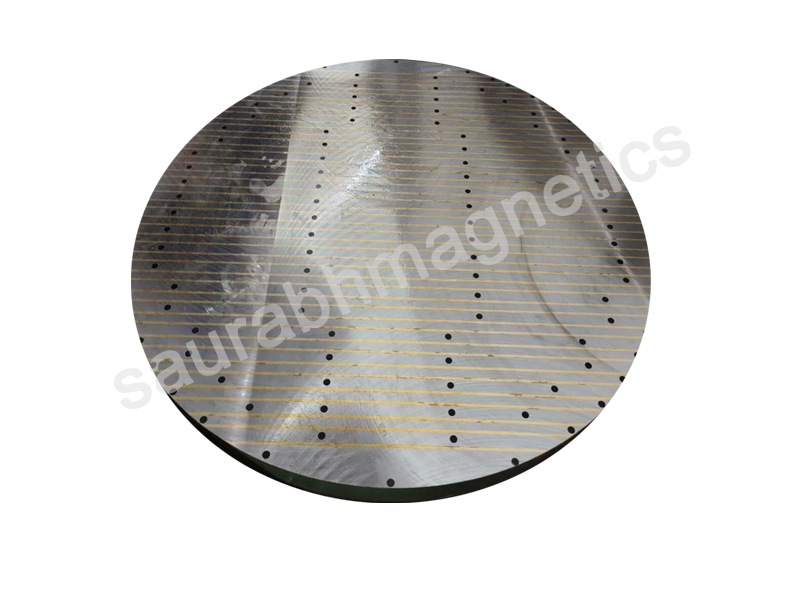

Electro Permanent Magnetic Chucks

We are engaged in offering Electromagnetic Chucks. These products are very efficient for heavy cutting with milling machine shaper, planer, plano miller. It shows the power for the thick work and the high speed cutting operation. Moreover, these panels can be availed in various sizes, grades and other specifications as per the patrons’ needs and demands. Professionals of our organization holds years of experience and are capable of providing appropriate solutions to the clients.

Features:

• Work holding device for Milling machines.

• COLD DEVICE as it doesn't require power continuously except for short period of activation & deactivation.

• Suitable for light milling i.e. 1-3 mm depth of cut at recommended speed & feed.

• Maximum material removal is possible.

• Economical for operation & maintenance.

• No accidents due to power failure.

• Slippering force is 2.5 - 3 Kg/cm².

• Vertical Lifting Force is 35 - 40 Kg/cm².

• Variable supply unit to vary power which helps in alignment of jobs.

• Chuck is tested for Slippering force, Waterproof test, Temperature rise test, Electrical & Demagnetizing tests.

• Good quality & standard electrical accessories.

• We also manufacture Special chucks to suit individual requirement.

Sr. No. |

Cat No. |

Size (mm) |

1. |

SMP-8001 |

600 L x 300 W x 110 H |

2. |

SMP-8002 |

750 L x 300 W x 110 H |

3. |

SMP- 8003 |

1000 L x 300 W x 110 H |

4. |

SMP- 8004 |

1500 L x 300 W x 110 H |

5. |

SMP- 8005 |

600 L x 400 W x 110 H |

6. |

SMP- 8006 |

750 L x 400 W x 90 H |

7. |

SMP-8007 |

1000 L x 400 W x 90 H |

8. |

SMP-8008 |

1500 L x 400 W x 90 H |

| 9. |

SMP CONTROL UNIT WITH VARIABLE SUPPLY |