Sine-Table

Used for Precision measurement, setting of angles & Light machining.

Accuracy for Square ness, Flatness & Parallelism within 0.010mm upto 200L & 0.015mm upto 450L.

Angle can be set within ±5 seconds.

Centre Distance between roller is within 0.005mm.

Made from high quality alloy steel.

Hardness - 60 ± 2 Rc & Tempered.

Magnetic Table for job holding.

Firm hinged clamp to reduce possibility of distortion.

Magnetic Chuck with fine Pitch (1.5mm)

SR.No. |

Cat No. |

Size (mm) |

Center Distance |

Inclination |

1. |

SMP-15001 |

150 L x 120 W x 65 H |

70 |

0 - 45º |

2. |

SMP-15002 |

250 L x 150 W x 65 H |

100 |

0 - 45º |

3 |

SMP-15003 |

300 L x 150 W x 65 H |

100 |

0 - 45º |

4. |

SMP-15004 |

450 L x 150 W x 65 H |

100 |

0 - 45º |

5. |

SMP-15005 |

450 L x 150 W x 65 H |

150 |

0 - 45º |

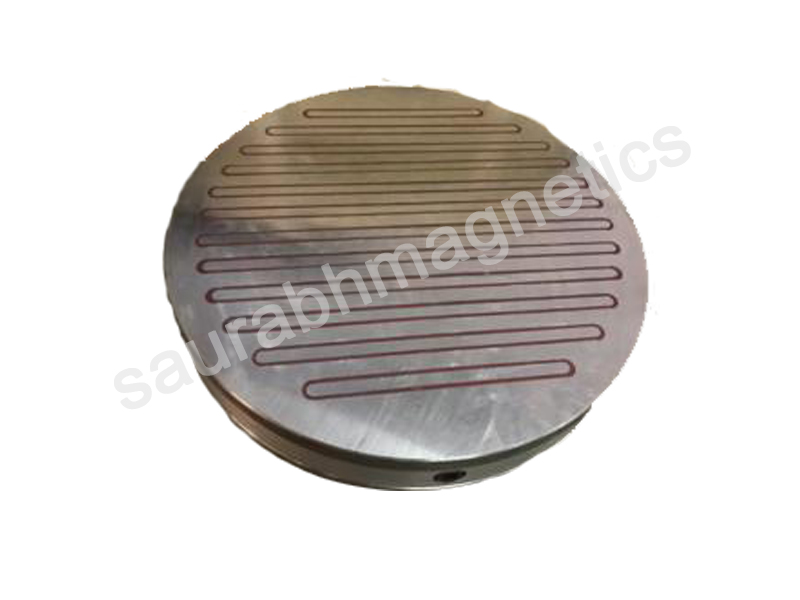

Round Permanent Magnetic Chuck

Clients can take advantage from us a wide range of Round Magnetic Chucks. Offered range of these products is designed using quality-approve raw material that is acquired from the dependable vendors of the market. In various industrial processes, it is widely used for holding ferro-magnetic work pieces owing to its magnetic properties. Offered lights are made using best quality material which we sourced from the trustworthy vendors of the market. These are well known due to their accurate dimensions.

Holding device for Rotary surface grinding and also for Lathe and Cylindrical grinding machines.

Accuracy as per IS : 4816 – 1987.

Magnetic pull is 20-40% more than IS specification.

Assembled with powerful Magnets.

ON-off by Allen key.

Sr. No. |

Cat No. |

Size (mm) |

Pole Gap (mm) |

1 |

SMP-4001 |

Ø 150 x 60 H |

14 |

2 |

SMP-4002 |

Ø 160 x 60 H |

16 |

3 |

SMP-4003 |

Ø 175 x 60 H |

16 |

4 |

SMP-4004 |

Ø 200 x 60 H |

16 |

5 |

SMP-4005 |

Ø 225 x 65 H |

16 |

6 |

SMP-4006 |

Ø 250 x 60 H |

19 |

7 |

SMP-4007 |

Ø 300 x 70 H |

19 |

8 |

SMP-4008 |

Ø 375 x 70 H |

19 |

9 |

SMP-4009 |

Ø 400 x 70 H |

19 |

10 |

SMP-4010 |

Ø 450 x 70 H |

19 |

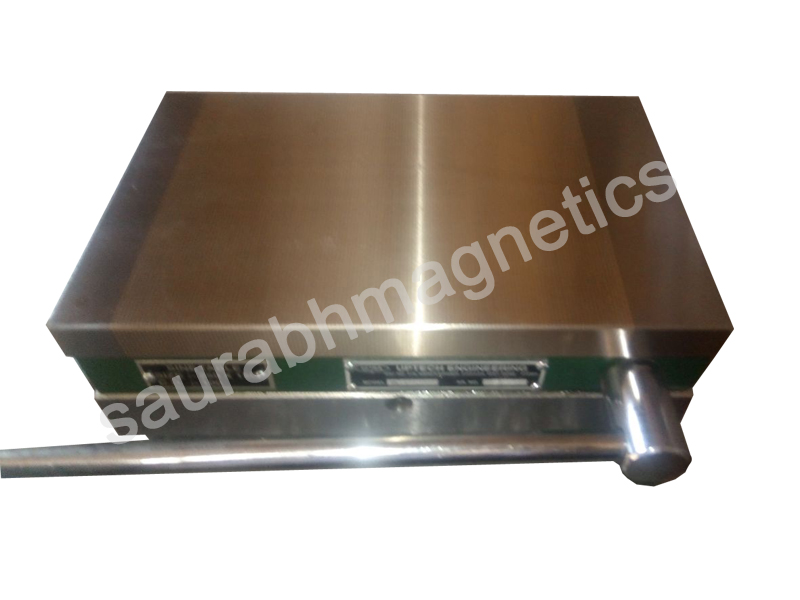

Electro Permanent Magnetic Chucks

We are engaged in offering Electromagnetic Chucks. These products are very efficient for heavy cutting with milling machine shaper, planer, plano miller. It shows the power for the thick work and the high speed cutting operation. Moreover, these panels can be availed in various sizes, grades and other specifications as per the patrons’ needs and demands. Professionals of our organization holds years of experience and are capable of providing appropriate solutions to the clients.

Work holding device for Milling machines.

COLD DEVICE as it doesn't require power continuously except for short period of activation & deactivation.

Suitable for light milling i.e. 1-3 mm depth of cut at recommended speed & feed.

Maximum material removal is possible.

Economical for operation & maintenance.

No accidents due to power failure.

Slippering force is 2.5 - 3 Kg/cm².

Vertical Lifting Force is 35 - 40 Kg/cm².

Variable supply unit to vary power which helps in alignment of jobs.

Chuck is tested for Slippering force, Waterproof test, Temperature rise test, Electrical & Demagnetizing tests.

Good quality & standard electrical accessories.

We also manufacture Special chucks to suit individual requirement.

Sr. No. |

Cat No. |

Size (mm) |

1. |

SMP-8001 |

600 L x 300 W x 110 H |

2. |

SMP-8002 |

750 L x 300 W x 110 H |

3. |

SMP- 8003 |

1000 L x 300 W x 110 H |

4. |

SMP- 8004 |

1500 L x 300 W x 110 H |

5. |

SMP- 8005 |

600 L x 400 W x 110 H |

6. |

SMP- 8006 |

750 L x 400 W x 90 H |

7. |

SMP-8007 |

1000 L x 400 W x 90 H |

8. |

SMP-8008 |

1500 L x 400 W x 90 H |

| 9. | SMP CONTROL UNIT WITH VARIABLE SUPPLY | |

Fine Pole Magnetic Chuck

We are one of the most reckoned organizations engaged in offering Magnetic Chucks. In various industrial processes, it is widely used for holding ferro-magnetic work pieces owing to its magnetic properties. These products are appreciated by our clients as they provide optimum performance without any disturbance.

Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion machines.

Fine Pitch (5 + 1) makes it suitable to hold very thin & small jobs.

The working face & bottom face is perfectly parallel.

Poles individually magnetized for full loading power.

Suitable to hold thin & small jobs.

Bottom plate has suitable extension to clamp on table..

Better magnetic grip due to close pole.

Easy operated ON-OFF lever.

Sr. No. |

Cat No. |

Size |

Ploe Gap (mm) |

Pole Pitch (mm) |

1. |

SMP-2001 |

250 L x 150 W x 65 H | 5 |

12 |

2. |

SMP-2002 |

300 L x 150 W x 65 H | 5 |

12 |

3. |

SMP-2003 |

300 L x 200 W x 65 H |

5 |

12 |

4. |

SMP-2004 |

350 L x 150 W x 65 H |

5 |

12 |

5. |

SMP-2005 |

400 L x 150 W x 65 H |

5 |

12 |

6. |

SMP-2006 |

450 L x 150 W x 70 H | 5 |

12 |

7. |

SMP-2007 |

450 L x 200 W x 70 H | 5 |

12 |

8. |

SMP-2008 |

500 L x 200 W x 70 H | 5 |

12 |

9. |

SMP-2009 |

600 L x 200 W x 70 H | 5 |

12 |

10. |

SMP-2010 |

450 L x 250 W x 70 H | 5 |

12 |

11. |

SMP-2011 |

450 L x 300 W x 70 H | 5 |

12 |

12. |

SMP-2012 |

600 L x 250 W x 70 H | 5 |

12 |

13. |

SMP-2013 |

600 L x300 W x 70 H | 5 |

12 |

14. |

SMP-2014 |

750 L x 250 W x 70 H | 5 |

12 |

Micro Fine Pitch Magnetic Chuck

We are one of the most reckoned organizations engaged in offering Magnetic Chucks. In various industrial processes, it is widely used for holding ferro-magnetic work pieces owing to its magnetic properties. These products are appreciated by our clients as they provide optimum performance without any disturbance.

Holding Device for VMC milling machine , CNC milling machine & manual milling machine

Accuracy as per IS : 4816 - 1987.

Assembled with powerful Magnets.

Magnetic pull is 40-70% more than IS specification.

Bottom plate has suitable extension to clamp on table.

Easy operated ON-OFF lever.

Sr. No. |

Cat No. |

Size (mm) |

Pole Pitch (mm) |

1 |

SMP 3001 |

250 L x 150 W x 60 H |

1.5 |

2 |

SMP 3002 |

300 L x 150 W x 60 H |

1.5 |

3 |

SMP 3003 |

350 L x 150 W x 60 H |

1.5 |

4 |

SMP 3004 |

400 L x 150 W x 60 H |

1.5 |

5 |

SMP 3005 |

450 L x 150 W x 60 H |

1.5 |

Through Pole Magnetic Chuck

We are one of the most reckoned organizations engaged in offering Magnetic Chucks. In various industrial processes, it is widely used for holding ferro-magnetic work pieces owing to its magnetic properties. These products are appreciated by our clients as they provide optimum performance without any disturbance.

Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion machines & also for light milling.

The working face & bottom face are perfectly parallel.

Assembled with powerful Magnets.

Poles individually magnetized for full loading power.

Magnetic pull is 40-70% more than IS specification.

Bottom plate has suitable extension to clamp on table.

Better magnetic grip due to close poles.

Suitable to hold thin & small jobs.

Easy operated ON-OFF lever.

Sr. No. |

Cat No. |

Size |

Ploe Gap (mm) |

Pole Pitch (mm) |

1. |

SMP-2001 |

250 L x 150 W x 65 H | 8 |

18 |

2. |

SMP-2002 |

300 L x 150 W x 65 H | 8 |

18 |

3. |

SMP-2003 |

300 L x 200 W x 65 H |

8 |

18 |

4. |

SMP-2004 |

350 L x 150 W x 65 H |

8 |

18 |

5. |

SMP-2005 |

400 L x 150 W x 65 H |

8 |

18 |

6. |

SMP-2006 |

450 L x 150 W x 70 H | 8 |

18 |

7. |

SMP-2007 |

450 L x 200 W x 70 H | 8 |

18 |

8. |

SMP-2008 |

500 L x 200 W x 70 H | 8 |

18 |

9. |

SMP-2009 |

600 L x 200 W x 70 H | 8 |

18 |

10. |

SMP-2010 |

450 L x 250 W x 70 H | 8 |

18 |

11. |

SMP-2011 |

450 L x 300 W x 70 H | 8 |

18 |

12. |

SMP-2012 |

600 L x 250 W x 70 H | 8 |

18 |

13. |

SMP-2013 |

600 L x300 W x 70 H | 8 |

18 |

14. |

SMP-2014 |

750 L x 250 W x 70 H | 8 |

18 |

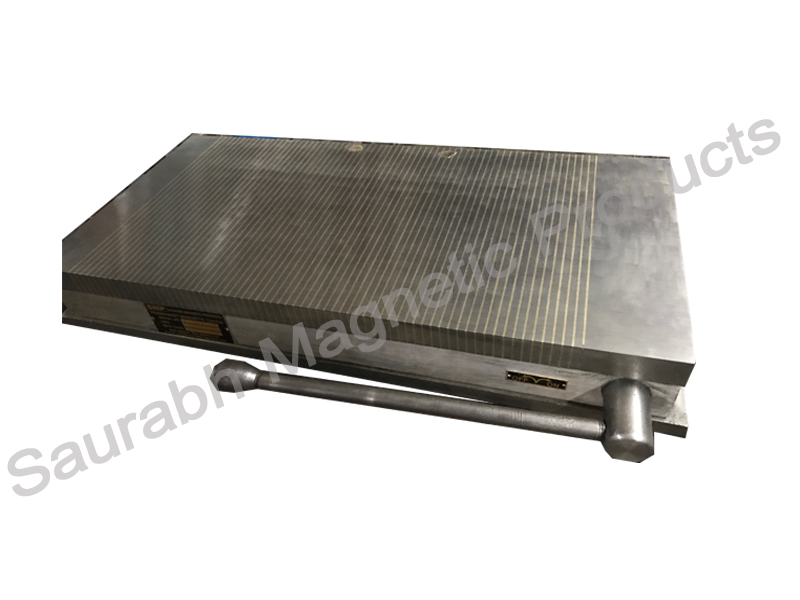

Permanent Magnetic Chucks

We are offering a wide variety of Permanent Magnetic Chucks. These high powered are widely appreciated by our customers for its dimensional accuracy and effective functioning. These are completely tested on various parameters by our experts before they are dispatched to our clients. While making these Permanent Magnetic Chucks, we make use of high grade raw material and latest technology. Offered are highly reckoned among our clients due to their superior finish and competitive prices. We also assure timely delivery of our products.

Cost effective

Reliable.

Highly demanded.

Code No. |

Size |

Ploe Pitch |

SMP-83701 |

300L x 150W |

9 mm |

SMP-83702 |

450L x 150W |

9 mm |

SMP-83703 |

300L x 200W |

9 mm |

SMP-83704 |

450L x 200W |

9 mm |

SMP-83705 |

500L x 200W |

9 mm |

SMP-83706 |

600L x 200W |

9 mm |

SMP-83707 |

450L x 250W |

11 mm |

SMP-83708 |

500L x 250W |

11 mm |

SMP-83709 |

600L x 250W |

11 mm |

SMP-837010 |

450L x 300W |

11 mm |

SMP-837011 |

600L x 300W |

11 mm |

SMP-837012 |

750L x 250W |

11 mm |

SMP-837013 |

750L x 300W |

11 mm |

Sine-Table

We are one of the most reckoned organizations engaged in offering Magnetic Chucks. In various industrial processes, it is widely used for holding ferro-magnetic work pieces owing to its magnetic properties. These products are appreciated by our clients as they provide optimum performance without any disturbance.

Used for Precision measurement, setting of angles & Light machining.

Accuracy for Square ness, Flatness & Parallelism within 0.010mm upto 200L & 0.015mm upto 450L.

Angle can be set within ±5 seconds.

Centre Distance between roller is within 0.005mm.

Made from high quality alloy steel.

Hardness - 60 ± 2 Rc & Tempered.

Magnetic Table for job holding.

Firm hinged clamp to reduce possibility of distortion.

Magnetic Chuck with fine Pitch (1.5mm).

SR.No. |

Cat No. |

Size (mm) |

Center Distance |

Inclination |

1. |

SMP-15001 |

150 L x 120 W x 65 H |

70 |

0 - 45º |

2. |

SMP-15002 |

250 L x 150 W x 65 H |

100 |

0 - 45º |

3 |

SMP-15003 |

300 L x 150 W x 65 H |

100 |

0 - 45º |

4. |

SMP-15004 |

450 L x 150 W x 65 H |

100 |

0 - 45º |

5. |

SMP-15005 |

450 L x 150 W x 65 H |

150 |

0 - 45º |

Electro Magnetic Round Chuck

Work holding device for Rotary surface grinding machine & lathe machines.

Each pole is having separate coil, as such very strong & even magnetic flux is generated.

Magnetic pull is 30-50% more then IS specification.

Mag - D - Mag with variable control unit allows to neutralize the residual magnetism precisely , using a microprocessor based control circuitry.

Variable supply for varying power which helps in alignment & removing of warpages of thin jobs.

Chuck is tested for Slippering force, Waterproof test.

Temperature rise test, Electrical & Demagnetizing tests.

Sr. No. |

Cat No. |

Size (mm) |

Circular Pole Gap (mm) |

1. |

SMP-17001 |

Ø300 X 100H |

10 + 5 |

2. |

SMP-17002 |

Ø450 X 100H |

10 + 5 |

3. |

SMP-17003 |

Ø600 X 100H |

10 + 5 |

4. |

SMP-17004 |

Ø750 X 100H |

10 + 5 |

5. |

SMP-17005 |

Ø1000 X 100H |

10 + 5 |

5A. |

"SMP" MAG D- MAG WITH VARIABLE CONTROL UNIT |

2 Amp. |

|

5B. |

"SMP" MAG D- MAG WITH VARIABLE CONTROL UNIT |

2 Amp. & above |

|

Electro Magnetic Chuck

Work holding device for surface grinding machines.

Each pole is having separate coil, as such very strong & even magnetic flux is generated.

Assembled with powerful Magnets.

Magnetic pull is 40-70% more than IS specification.

Bottom plate has suitable extension to clamp on table.

Easy operated ON-OFF lever.

Sr.No. |

Cat No. |

Size |

Ploe Gap (mm) |

Pole Pitch (mm) |

1 |

SMP-1001 |

200 L x 100 W x 60 H |

12 |

26 |

2 |

SMP-1002 |

200 L x 150 W x 60 H |

12 |

26 |

3 |

SMP-1003 |

250 L x 150 W x 60 H |

12 |

26 |

4 |

SMP-1004 |

300 L x 150 W x 60 H |

12 |

26 |

5 |

SMP-1005 |

300 L x 200 W x 65 H |

12 |

26 |

6 |

SMP-1006 |

350 L x 150 W x 65 H |

12 |

26 |

7 |

SMP-1007 |

400 L x 150 W x 65 H |

12 |

26 |

8 |

SMP-1008 |

450 L x 150 W x 65 H |

12 |

26 |

9 |

SMP-1009 |

450 L x 200 W x 70 H |

12 |

26 |

10 |

SMP-1010 |

500 L x 200 W x 70 H |

12 |

26 |

11 |

SMP-1011 |

600 L x 200 W x 70 H |

12 |

26 |

12 |

SMP-1012 |

450 L x 250 W x 70 H |

12 |

26 |

13 |

SMP-1013 |

450 L x 300 W x 70 H |

12 |

26 |

14 |

SMP-1014 |

600 L x 250 W x 70 H |

12 |

26 |

15 |

SMP-1015 |

600 L x 300 W x 70 H |

12 |

26 |

16 |

SMP-1016 |

750 L x 250 W x 70 H |

12 |

26 |

.png)